01

Aiming to be a responsible corporate citizen.

We achieved significant progress in our primary Environmental, Social, and Governance ("ESG") domains, fortifying our dedication to sustainability and effectively implementing our sustainability initiatives. Transparency is still ingrained in our reporting and strategy. We hope that this reporting will help to improve confidence among our stakeholders, which include our employees, customers, suppliers, partners, shareholders, peers, and communities.

I am glad to present our goals and our accomplishments in the report. While Century Bond Bhd (CBB) is constantly reminded of and challenged about what "sustainability" means to us, we must first examine our own operations in order to make the necessary internal changes before we can work towards a sustainable future and maintain the United Nations Sustainable Development Goals ("UNSDGs"). By streamlining the process of producing this Report, we were able to take a step closer to adopting optimal sustainability practices this time around. We optimise the narratives while preserving authenticity and comprehensiveness, which allowed us to condense the Report's page count.

KPI PERFORMANCE INDICATORS FOR MOST MATERIAL MATTERS

The Sustainability Reports are extraction from Kumpulan Perangsang Selangor Berhad Sustainability Report. Full report may be accessed via https://kps.com.my/index.php/sustainability/sustainability-report

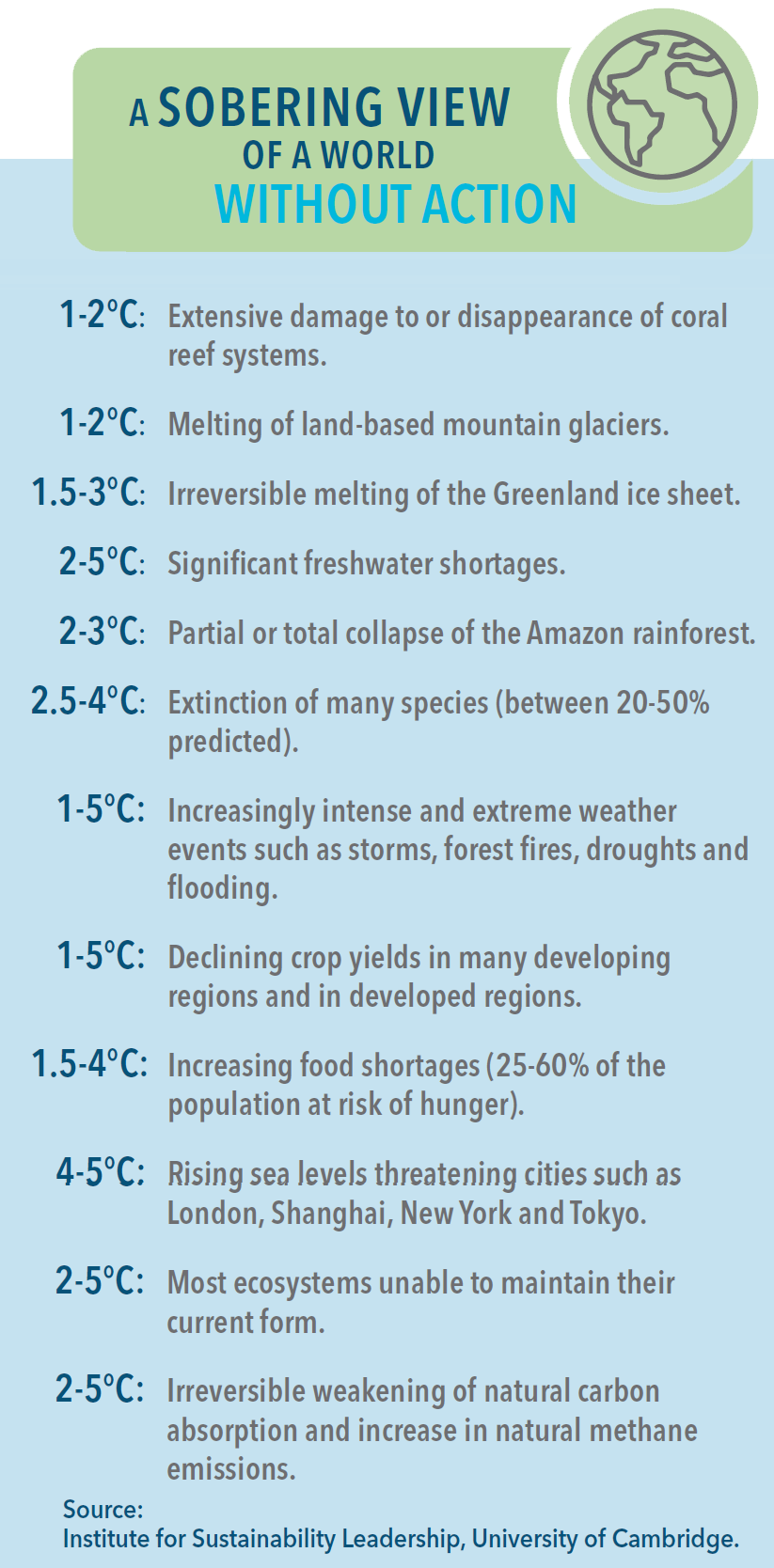

A comprehensive strategy encompassing technology, policy, and individual action is needed to combat climate change. To reduce carbon emissions, governments need to invest in renewable energy sources, set aggressive emissions reduction objectives, and pass legislation. To create green technology, businesses need to innovate and implement sustainable practices. By adopting new habits like taking public transit, using less energy, and purchasing eco-friendly goods and services, individuals may help reduce their carbon footprint and make a positive impact on the environment. In order to reduce the effects of climate change and provide a sustainable future for future generations, cooperation between governments, businesses, and individuals is essential.

In order to combat climate change, a multifaceted strategy involving technology, policy, and individual action is needed. To reduce carbon emissions, governments need to invest in renewable energy, set aggressive emissions reduction objectives, and pass legislation. In order to create green technologies, businesses need to innovate and implement sustainable practices. People can help by changing their lifestyles to reduce their carbon footprint, which includes taking public transit, using less energy, and patronising green goods and services. Governments, businesses, and individuals must work together to reduce the effects of climate change and build a sustainable future for future generations.

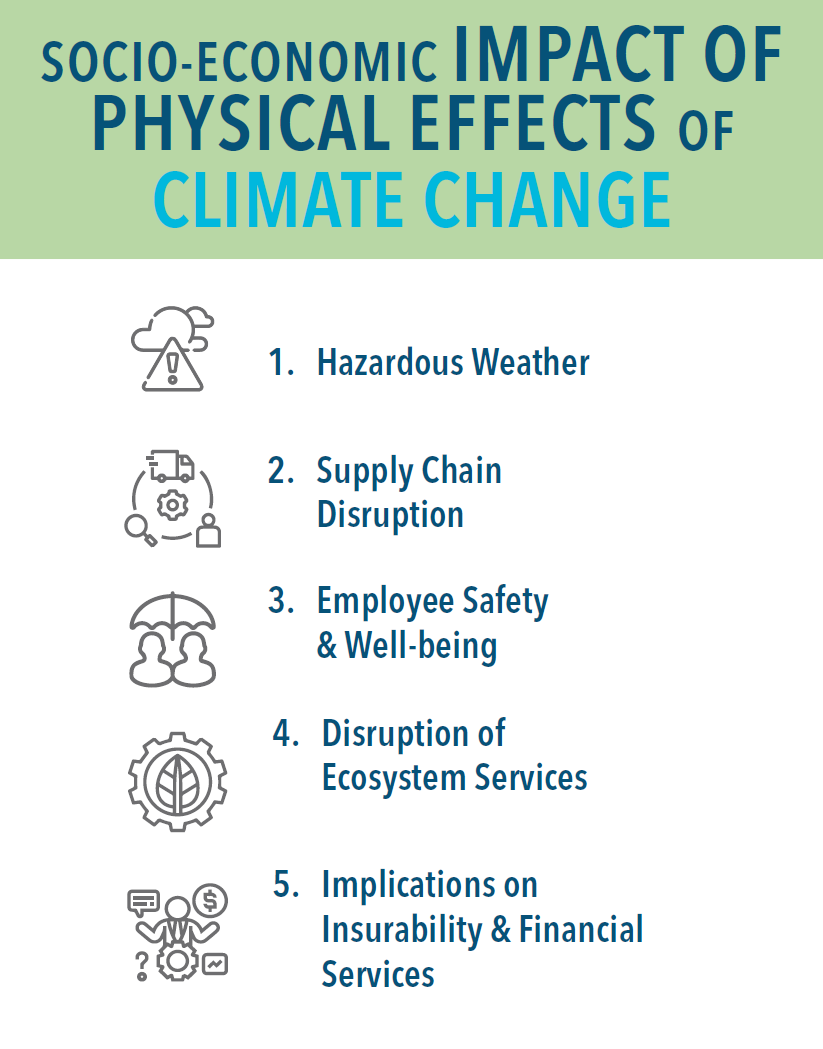

In other nations where our value chains are located, such as Malaysia, Europe, China, Indonesia, and Vietnam, unusual storm patterns, intense rain, flash floods, and landslides, were additional physical risk manifestations. Research indicates that as the years and decades go by, the effects of climate change will get more severe. Examining these fundamental issues about how we have been and will continue to run our manufacturing operations to chart our business growth, how we depend on the environment, and how we can collaborate with businesses, governments, and non-profit organisations ("NGOs") to accomplish more than we could alone, for the greater benefit of all parties involved, was therefore only necessary and timely.

In the annals of our company's history, a significant chapter has been marked not only by a rebranding and the evolution of our visual identity but also by a pivotal shift towards sustainability.

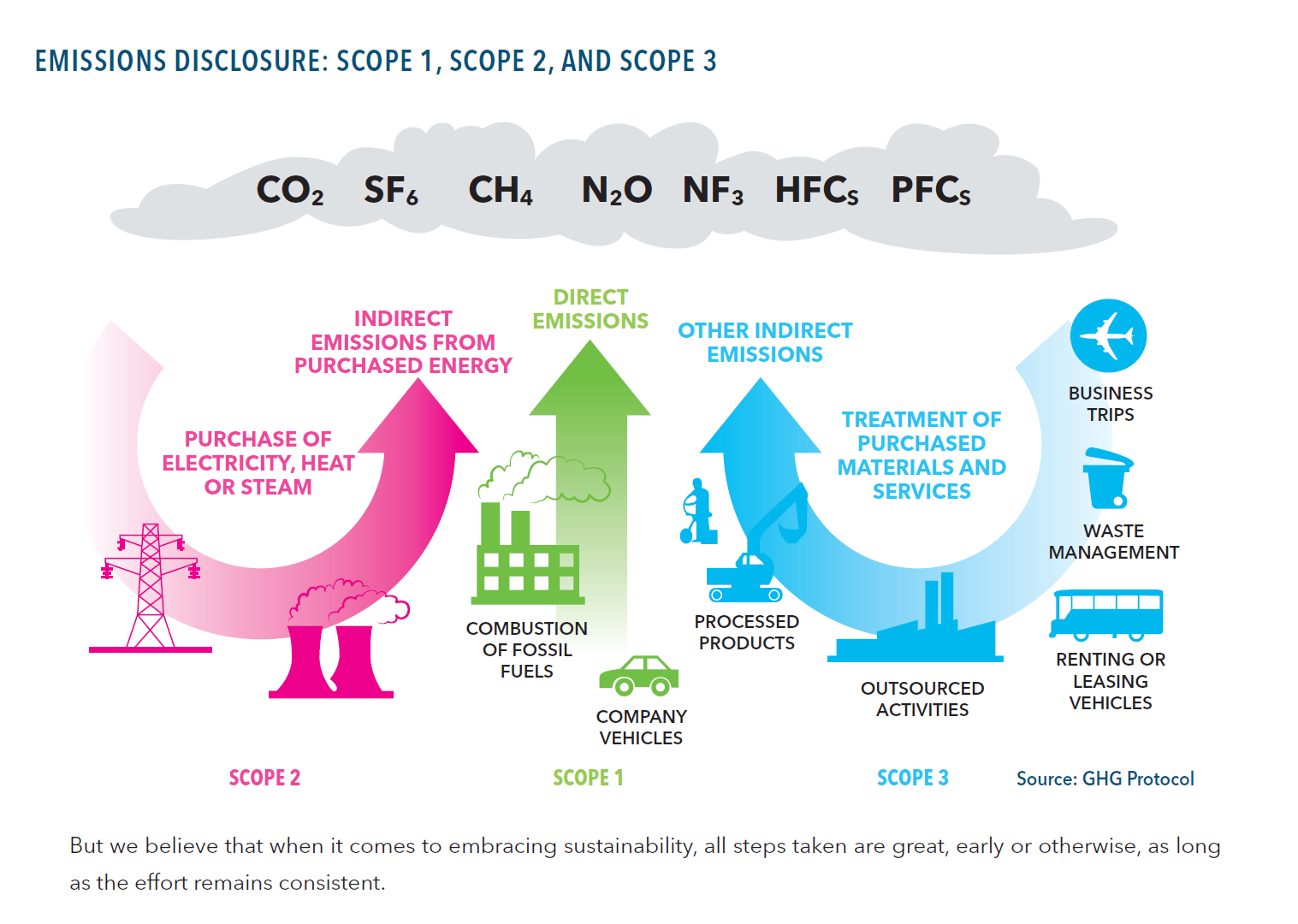

This milestone signifies our commitment to addressing pressing environmental concerns, particularly our greenhouse gas emissions.

By monitoring and managing our emissions, we aim to contribute to the global effort to mitigate climate change and limit global warming to 1.5°C above pre-industrial levels.

Through our inaugural disclosure on Scope 1 and Scope 2 emissions, we've taken a crucial step towards understanding and reducing our carbon footprint.

This journey marks a fundamental shift in our operations, as we strive to embrace sustainability as a core principle guiding our business decisions and initiatives.

As in the past, the Report conveys our support for the UNSDGs by embedding and integrating the related targets into our business strategies and sustainability initiatives. We commit ourselves to considering environmental and social aspects in addition to financial aspects when making our business decisions, recognising their value in ensuring a sustainable, resilient, and inclusive future.

Integrated packaging solutions provider driven by five business divisions, namely Offset, Carton, Paper, Plastics and Original Equipment Manufacturer (“OEM”) for Consumer Products. The Offset division is currently leading the business operating from three plants across Malaysia and Indonesia. The Carton division covers an essential industry with a presence in the Northern, Central and Southern regions of Malaysia. The Paper division operates from three plants across Malaysia and Indonesia. The other two divisions, Plastics and OEM for Consumer Products, continue to support the businesses in providing integrated packaging solutions to customers from the Electrical & Electronics and retail sectors via its plant in Senai.

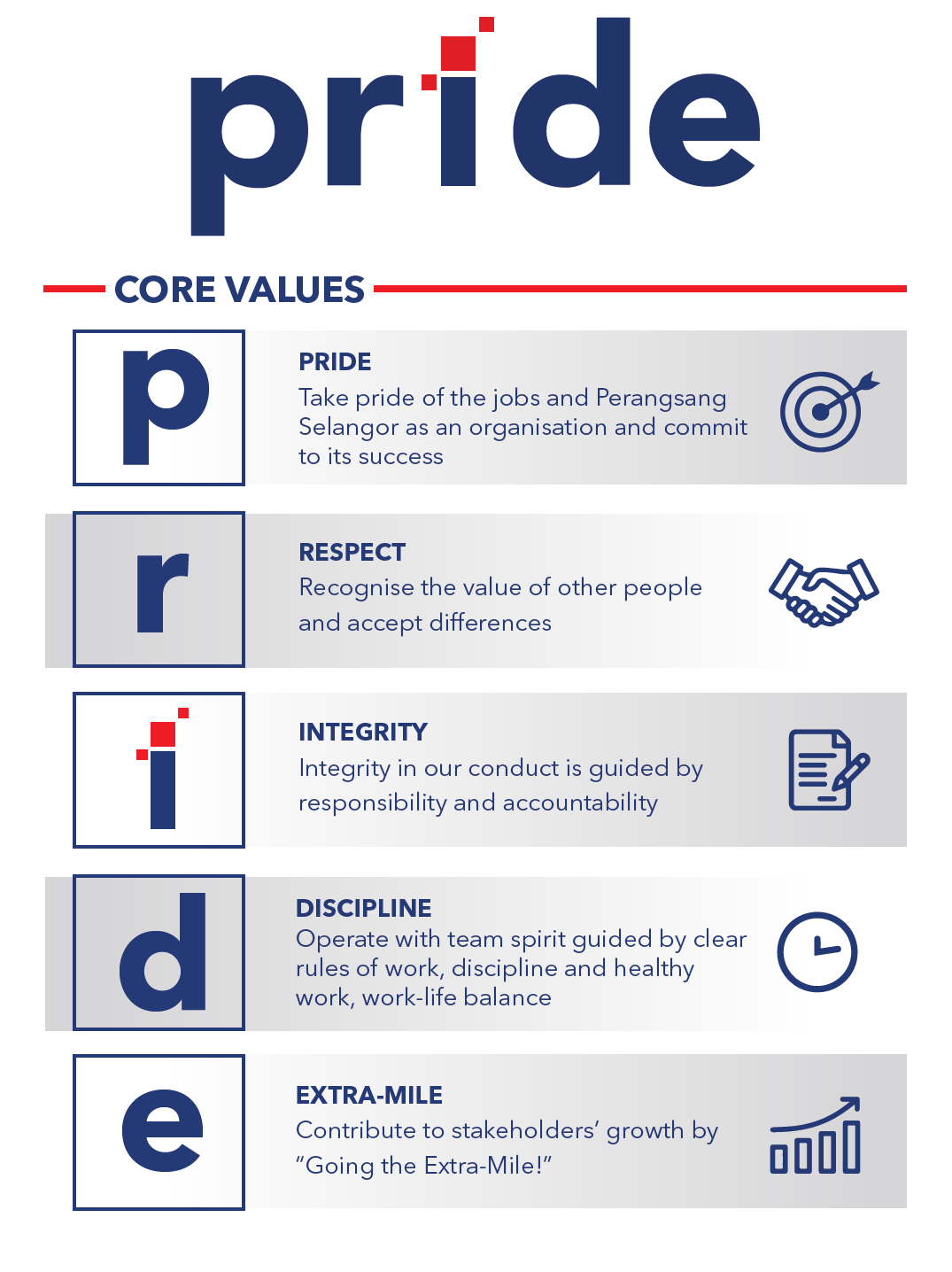

As a subsidiary of public listed investment holding of Kumpulan Perangsang Selangor Berhad (“KPS”), we seek to embed sustainability in our business by operating responsibly through the integration of three core sustainability pillars (Economic, Environment, Social) prescribed by Bursa Malaysia Securities Sustainability Reporting Guide and in compliance with Bursa Malaysia’s Main Market Listing Requirement Practise Note 9 Paragraph 6.

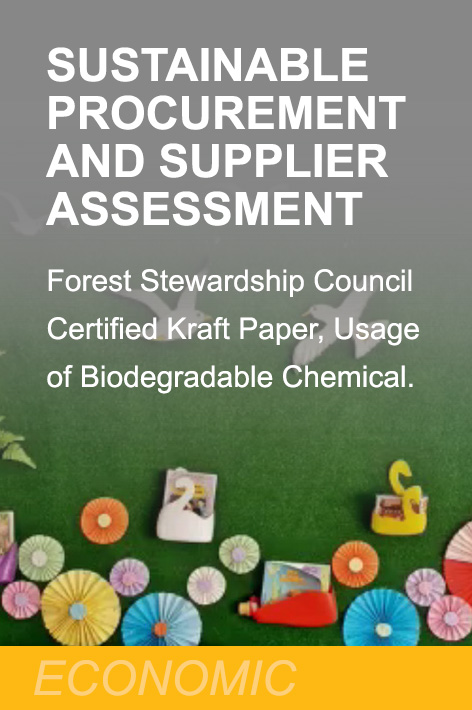

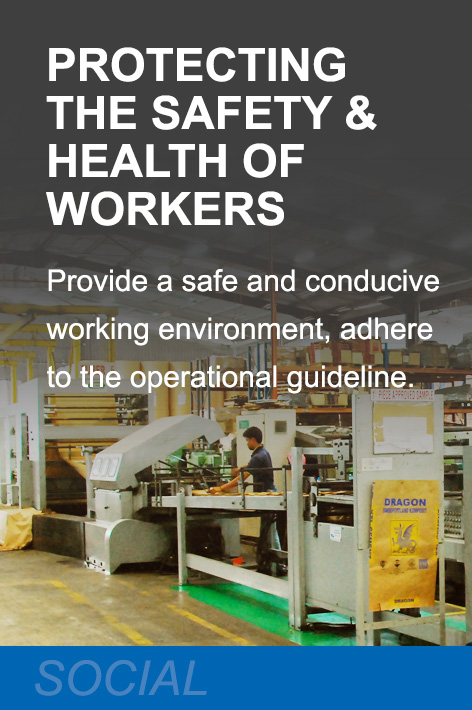

The Economic outlines our efforts in ensuring business sustainability via well-defined strategies, the ensuing action plans, and long-term value creation plans. It also elaborates on how these efforts directly or indirectly contribute to developing the local economy and our interaction with the economic system. In the Environment pillar, we share our initiatives in minimizing the intensity of our environmental footprint. The Social outlines our engagement with the diverse group of stakeholders, narrating how these approaches help us achieve a far greater positive impact on our stakeholder network.

Proactive steps were identified to align ourselves with the following selected United Nations Sustainability Development Goals.

To contribute to sustainable development by balancing the economic, environmental and social sustainability aspects of the business for the benefit of all stakeholders.

To achieve business and operational excellence through responsible consideration and holistic integration of the economic, environmental, and social risks and opportunities.

01

Aiming to be a responsible corporate citizen.

02

Upholding the highest standards of governance and ethics.

03

Promoting sustainable business practices.

04

Limiting the negative impact of our business on the environment.

05

Building and maintaining strong relationships with stakeholders.

The first revision of the Sustainability Policy (“Policy”) was approved by the Board of Directors on 29 November 2018 to ensure the Group’s activities create long-term value for all our stakeholders by addressing Economic, Environmental, Social and Governance ("EESG") opportunities and risks. The Policy clearly states how the Group plans to advance sustainability across its different businesses and in the various sectors. The Group’s Policy was revised on 26 August 2021 to ensure that it stays relevant as a guiding principle by taken into account the latest practices and updated sustainability strategies.

Developing and implementing EES action plans and initiatives, as well as committing to measuring and monitoring the said initiatives;

Adhering to approved business plans and strategic direction, as well as to all applicable laws, regulations and standards;

Addressing environmental challenges and opportunities in our business activities;

Strengthening social well-being and community relationships;

Providing a conducive work environment and operating in a healthy, safe and efficient manner;

Maintaining effective engagement with all stakeholders and Implement effectual governance structure and practice for sustainable development;

No Poverty

Good Health and Well-being

Quality Education

Gender Equality

Affordable and Clean Energy

Decent Work and Economic Growth

Industry, Innovation and Infrastructure

Sustainable Cities and Communities

Responsible Consumption and Production

Climate Action

Life Below Water

Life and Land

Reduced Inequalities

Partnerships for the Goals

Clean Water and Sanitation

Peace, Justice and Strong Institutions

The following set of Century Bond Bhd’s (“CBB”) initiatives towards the integration of sustainability into the business process are in accordance with the Global Reporting Initiative Standard: -

Social Responsible Activities & Corporate Events

Century Bond Bhd has launched a No Single-Use Plastic campaign on 6 January 2025. As part of this initiative, we provide all staff with reusable food containers and bottles, replacing disposable plastic items like single use plastic food containers and plastic bottles. This program offers multiple benefits: for staff, it leads to cost savings, as they no longer need to buy disposable items; convenience, with personal containers for meals and drinks; and healthier choices, by ensuring their food and beverages are stored safely. For an environmental perspective, this initiative helps cut down on plastic waste, reduce landfill and ocean pollution. This campaign supports our sustainability goals, enhances our brand image as an eco-conscious business, and promotes a positive workplace culture. Ultimately, this campaign is an essential step towards a cleaner, greener future, benefiting both the environment and the company’s long-term success.

06th Jan 2025, Century Bond Factory, Senai, Johor

On May 21, 2024, Century Bond Bhd demonstrated its commitment to Corporate Social Responsibility (CSR) by donating 1 unit Indoor LED Display Board to the Pejabat Pendidikan Daerah Kulai as part of their CSR program. The LED Board will be utilized in the Seminar Room, benefiting educators and officers who host various programs in the room. The official event was graced by Tuan Haji Mohd Kamal Bin Hj Ahmad Untong, the Pegawai Pendidikan Daerah Kulai, along with CBB CEO Mr. Alfred Goh Leng Hock, CBB Vice President of Corporate Services En. Zainal Abu Bakar, and Kulai District Education Officers. As part of its annual program, Century Bond Bhd has also donated 10 units of Xiaomi 55 inch smart TV to 7 schools in the Kulai district, as well as Pejabat Pendidikan Daerah Kulai. This initiative highlights Century Bond Bhd's dedication to supporting educational institutions and fostering community development through their CSR efforts.

21st May 2024, Pejabat Pendidikan Daerah Kulai, Kulai, Johor

Century Bond Bhd’s annual event for Bubur Lambuk 2024 was conducted on 28 March 2024. The employees got together and prepared the porridge with the hearts of sincerity and goodwill. The “Bubur” were given to all employees in the spirit of Ramadhan.

28th March 2024, Century Bond Factory, Senai, Johor

On 28 March 2024, Century Bond Bhd via its Corporate Social Responsibility (CSR) program with Pejabat Pendidikan Daerah Kulai has donated two (2) cutting-edge Xiaomi 55 inch smart TVs to Sekolah Menengah Agama Bandar Tenggara, Kota Tinggi, Johor with a vision to enhance the learning methods and provide diverse resources for the students to revolutionize their educational experience at the school.

The Xiaomi smart TVs will serve as a crucial tool in the students' academic journey, enabling them to access a wide range of educational content. The integration of appropriate subtitles will enhance their reading, listening, and vocabulary skills. By utilizing this technology, the students will have an engaging and immersive learning experience, opening up new avenues for their overall development.

28th March 2024, Sekolah Menengah Agama Bandar Tenggara, Kota Tinggi, Johor